PGDA

It increases the efficiency of well treatment due to the creation of high-frequency vibration during the firing of its elements that result in redistribution of the energy of the combusted products into the oscillatory component.

The generator offered to oil companies is simpler in its make and in its assembly than other domestic-made devices at the basis of solid fuel, intended only for thermal gas chemical well treatments.

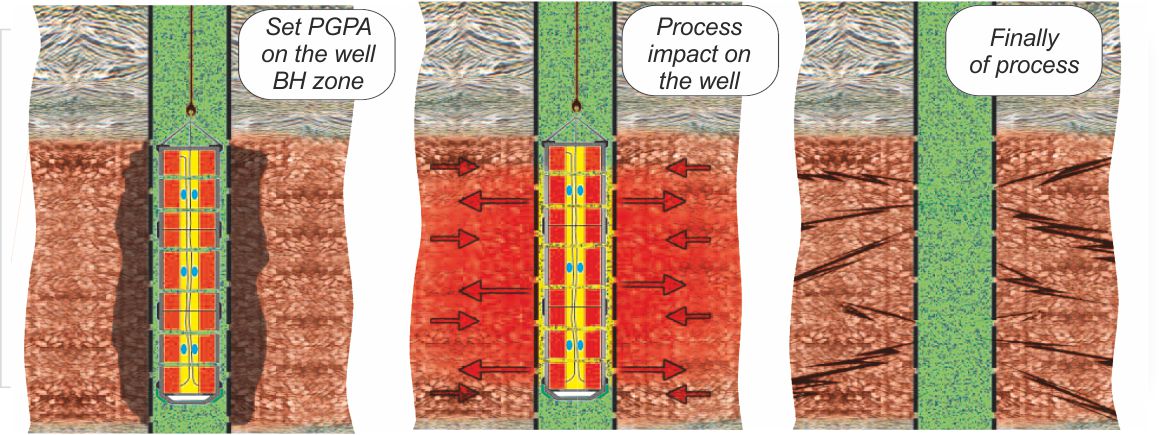

The process of PGDA combustion results in mechanical, thermal, physical/chemical and vibrating impact on the well BH zone, which in some specific moments make simultaneous multiple effect: mechanical, thermal, physical/chemical, vibration impact:

- Mechanical effect

- Thermal effect

- Physical/chemical effect

- Vibration effect.

Mechanical effect

results in arrangement of reservoir additional residual fractures after gas and HP reservoir fluid penetrate into the formation pores. Thus also result in the destruction of water/oil barriers that have been formed during the previous well operation, as well as in BH zone cleaning against the products of chemical reactions and the removal of sand/clay particles.

Thermal effect

- of the combusted products leads to the melting of asphalt/wax/paraffin sediments and strengthening of chemical reactions that take place in the reservoir.

Physical/chemical

- effect of the combusted products provides for the reduction of viscosity factors and oil/water interfacial tension, partial dissolution of carbonate rock and near-well cement.

Vibration effect

- at the well BH is achieved due to the generation of fluctuations, arising in the lateral channel, through radial openings and end faces of the elements as well as through acoustically transparent walls of the well.

The anticipated mechanism of such effect lies in the excitation of resonant fluctuations in separate particles and blocks with allocation of internal energy in the tight rock as secondary acoustic radiation.

The primary fluctuations in a combination with this radiation provide the influence upon physical/chemical properties of the fluid, cause changes in filtration parameters and formation fluid characteristics due to the partial degassing and subsequent dissolution of allocated gas, thus increasing the diameter of filtration channels, etc.

Finally they arrange the micro-fractures decreasing the reservoir heterogeneity rate, dropping the reservoir oil viscosity and increasing the total productivity of the well.